Service description

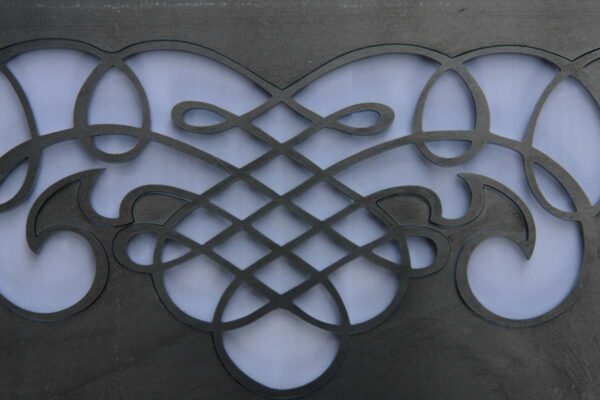

Today, Laser technology is indispensable part of industry. Laser cut is precise and with no burr, and additional treatment is not required.

The technology of laser metal cutting is based on focused laser ray which cuts metal. By quick machine programming it is possible to make small series, as well as big ones. When producing small series laser cutting is even many times over more cost-effective in comparison to stamping tools. It is due to the high price of tool when using stamping procedures or due to time required to treat a piece when using traditional technologies. Besides, it is very easy to change certain positions in a serie or to cut on same metal sheet more various positions.

Machines posess a programme for maximal material exploitability, which becomes prominent when talking about valuable materials such as stainless steel or aluminum.

This technology can be of use also when making constructional pieces, medical instruments, implatants, sprocket- wheels, chains, circular saws, saws, knifes, constructional elements, motor gaskets, flanges, furniture, laminated springs, fancy goods and other, and it has a wide range of use in both industry and shipbuilding industry.

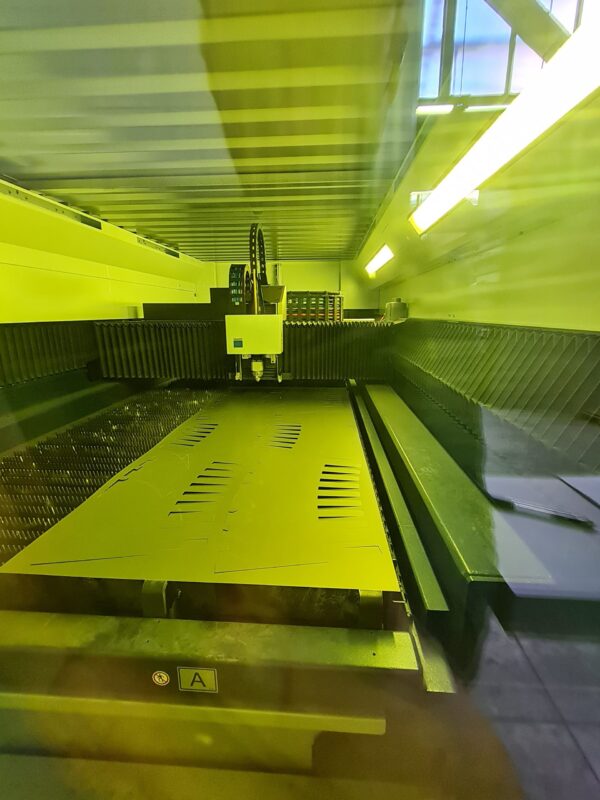

We have four laser machines:

Our new TRUMPF 3030 is fiber technology based. It can cut steel up to 32 mm, stainless steel up to 35 mm and aluminium up to 25 mm. We can also cut copper and brass up to 10 mm.

TRUMPF 3020 is a laser cutter that cuts metal sheets up to surface dimension of 1500x3000mm, and up to 20 mm in thickness, using CO2 technology and is specialized for thick sheets and stainless steel materials.

Our new laser cutter TRUMPF TL 3030, with higher cutting speed and integrated automatic pallet exchanger, enabled us to maximize production capacity and minimize time required to cut out a piece. Apropriate for metal sheets up to surface 1500×3000 mm with maximal thickeness up to 20 mm.

We are also able to cut wood and plastic materials, on our non metal laser cutter.

We cut materials up to thickeness:

Steel – up to 32 mm

Stainless steel – up to 35 mm

Aluminum – up to 25 mm

Copper/brass – up to 10 mm

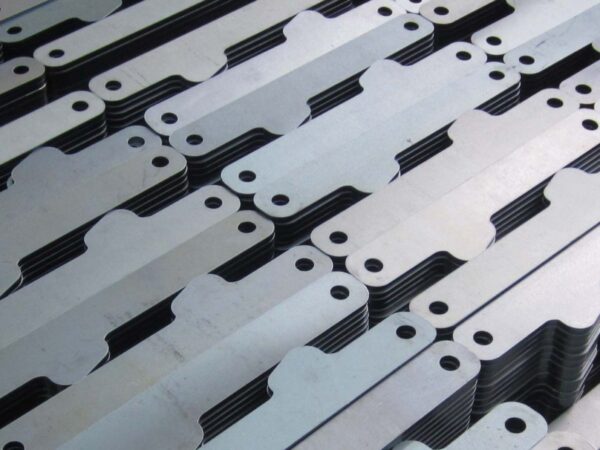

As an ISO 9001 Certified company, we specialize in the manufacture of laminations for the motor and generator industry as well as offer fabrication services for a wide range of industries. We set up a bussines model for 24/7 operation support for Turbine Generator and Hydro Generator Service applications. With investments in over 4 CNC Lasers, design and Support Teams, and Automation, our company is the best choice to tackle full core, highly quality, detail specification driven generator projects.

PRO understands the criticality of timing on these projects and the necessity for zero defects that can lead to extreme penalties. Our internal risk management assessment evaluates and mitigates potential risks within our business to assure On time delivery and zero defects investment and duplication of all critical manufacturing.

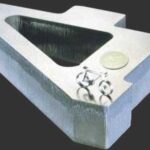

Reverse Engineered Drawings- Stator Core Assemblies, Rotor Rim Assemblies, Pole Lamination Assemblies, Exciters, Vent Assemblies, Finger Plate Assemblies, Stator Laminations, Rotor Laminations, Pole Laminations, Back Up Laminations

Lamination Manufacturing- Laser Cut Laminations, Rotor Rim Plates, Segmented Stator Laminations, Non Segmented Stator Laminations, Split Tooth Laminations, Step Back Laminations, Pole Laminations, Shims,

Vent Assemblies- Spot Welded Vent Assemblies, Riveted Vent Assemblies, MIG or TIG Welded Vent Plates, Back Up Laminations, Machined Fingers, Fabricated Fingers, Insulation Coating Applications, I-Beams, Bars

How to make an order?

- Along with inquiry, customer is sending a dwg. or dxf. drawing

- According to drawing, number of pieces, type and thickness of material, customer receieves quotation, which serves as a proforma invoice as well

- After the payment production is starting

Request offer

Your request has been sent!

Your request has been sent!  ERROR! Request is not sent! Please try again.

ERROR! Request is not sent! Please try again.